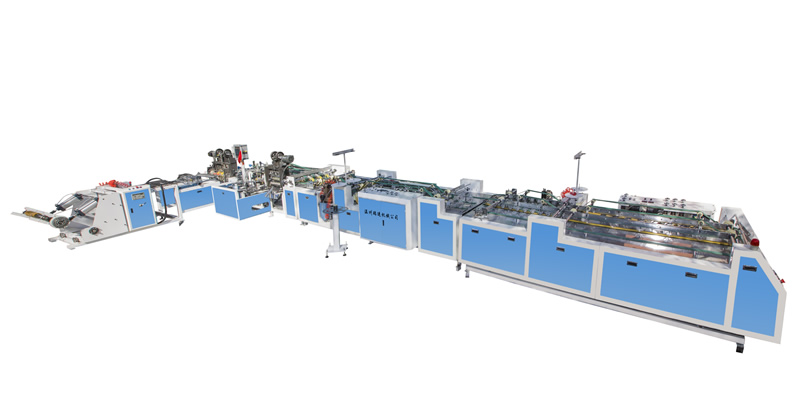

Valve pocket cutting and creasing double hot-melt back sealing machine

Features

1. The machine adopts automatic device, PLC control, touch screen operation, servo drive, cold cutting or hot cutting model can be selected.

2. Folding part: using servo operation, the folding size is uniform and flat, the incision knife is made of imported materials, the hot knife does not deform, realizes smoke-free environmental protection, the bag mouth is adhered, and the stitching is smooth.

3. Cold cutting knife: imported material, durable and practical.

4. The specifications of the folding mouth can be easily adjusted, and the length of the bag can be adjusted with one click.

5. Automatic feeding, automatic deviation correction, automatic benchmarking, automatic counting, batch delivery, disconnection alarm, fault and automatic stop of the connector

6. This machine is suitable for: ordinary seven-character valve pockets, color-printed seven-character valve bags, etc., cold glue back cover, hot glue back cover, etc., one machine for multiple purposes, one person operation

|

Cylinder Diameter |

≤1200mm |

|

Finished bag cutting width |

300-550mm |

|

Finished bag cutting length |

500-920mm |

|

Bag cutting speed |

35-40 pieces/min |

|

Bag cutting accuracy |

±1mm |

|

Total Power |

19KW |

|

Installation Dimensions |

(L) 12500*(W) 5000*(H) 1400mm |